Black Country Firm Reaches for The Stars

05 Feb 2024

Published in: Member News

Regent Engineering, has won a prestigious contract to supply antenna components for the world’s biggest international project in Astronomy

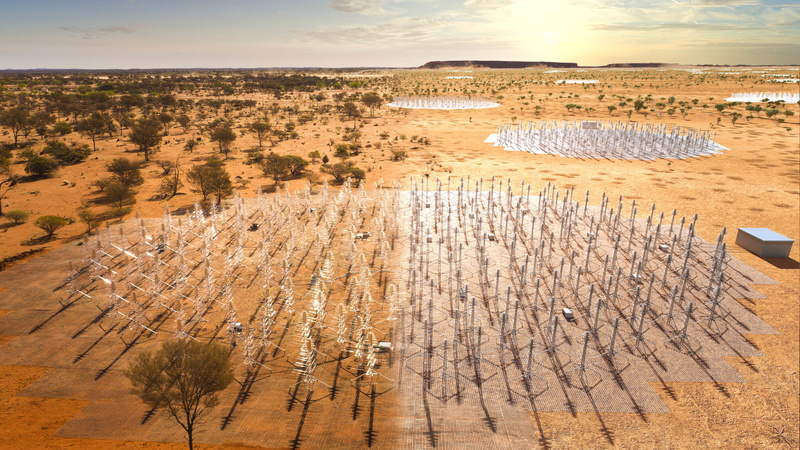

Darlaston pressings and Assemblies specialist, Regent Engineering, has won a prestigious contract to supply antenna components for the world’s biggest international project in Astronomy. Known as the Square Kilometre Array (SKA) the project will consist of over 131,000 low-frequency wire antennas (each like a large TV antenna), in the desert of Western Australia.

Together with an installation of large dish antennas located in the Karoo desert in South Africa the two installations will cover the entire range of radio frequencies, from 50 MHz up to 25 GHz, with unprecedented sensitivity, resolution, and sky coverage. The SKA will transform our view of the Universe in a number of key science areas, including, seeing how the first galaxies emerged, searching for the signatures of life in the universe and the presence of organic and biological molecules. The SKAO consortium involved in the project has headquarters at Jodell Bank in Cheshire and is a joint effort involving 14 countries.

Regent’s part of the €100m contract involves the supply of pressed metal components which form the main low frequency collecting components located at the of the top of the antenna assembly.

These high precision parts are stamped and formed, chemically cleaned, and then carefully packed for shipment to Italy for incorporation in the final antenna assembly, which is over 2 metres high and somewhat resembles a metal Christmas tree.

The first phase of production is now under way and will involve the supply of more than 250,000 components over the next two years, with a possible second phase of a similar size commencing in 2026.

In continuous production since 1941, Regent have the skills and experience to undertake the most complex pressed component and assembly supply projects. Our 50 strong, highly motivated and capable team is supported by an on-going capital investment programme which is aimed at maintaining a leading position in the market sectors we target.

Conventional Mechanical and Hydraulic presses from 5 Tonnes up to 700 Tonnes, incorporating large bed area machines, many with die cushions for complex formed shapes. Also, specialised machines for very long narrow strip piercing (up to 2200mm) and coil-fed progression presses up to 120 Tonnes. We have robotic and manual MIG welders for spot & projection welding to 75KVA spin & pop riveting mechanical assembly.

For more information regarding Regent Engineering, please visit our website here

Comments

Post A Comment

You must be logged in to post a comment. Please click here to login.